Case

The company focuses on the development of aircraft ground air-conditioning units by virtue of refrigeration electrical control technology and in-depth research on the needs of users

SF-100DG-DL PBB Mounted Aircraft Pre-conditioning Air Unit

Aircraft PCA unit

Aircraft PCA unit provides pre-conditioned air flow with required pressure and temperature to the aircraft when docking at PPB.

Specifications and standards:

The product is designed according to international AHM standard and CAAC MH/T6109-2014 specification.

Working conditions:

Working conditions T1:Ambient dry-bulb temperture 35℃,relative humidity 50%.

Working conditions T2:Ambient dry-bulb temperture 35℃,relative humidity 60%.

Working conditions T3:Ambient dry-bulb temperture 35℃,relative humidity 70%.

Working conditions T4:Ambient dry-bulb temperture 35℃,relative humidity 80%.

Technology advantages:

Rapid Cooling. Output temperature at duct can be cooled to 3℃ within 3 minutes at cooling mode, which can satisfy time critical short-stop flights.

Ultra-low temperature air supply. Airflow temperature at duct keeps under 2℃ during non-defrosting period.

By using intelligent defrosting fuzzy control method, defrosting interval is over one hour and defrosting period lasts about 4 minutes while the output temperature keeps under 5℃.

Wide?range?of?working?conditions. This is maybe the only machine in the market which can satisfy the requirements of all T1/T2/T3/T4 working conditions, with working temperature ranging -40℃~52℃ and relative humidity ranging 0~100%.

Capable of cooling all types of aircraft including Code-F A380 super jumbo.

Easy maintenance. By modular design, it is easy to replace components. Components are interconvertible to different unit types which can minimize spareparts varieties.

Maintenance staff can download and install our APP to check the units’working status and receive fault alarms anytime, which will reduce invalid site inspections and save maintenance cost.

Unit technical parameters:

| Description | Technical parameters |

| Weather conditions | T2/T3/T4 |

| Type of installation | Hanging type |

| Input power | AC380V 3N.50HZ |

| Type of compressors | Scroll type |

| Compressor Qty | 5Ea |

| Refrigerant and Qty | R22/95kg |

| Air Flow | 8100m3/h |

| Cooling Capasity | 206kw(T2)/232kw(T3)/260kw(T4) |

| External Static Pressure | 6700Pa |

| Heating power | 85kw |

| Cooling power | 120kw(T2)/136kw(T3)/156kw(T4) |

| Centrifugal fan power | 37kw |

| Noise | ≤85db(A) |

| Output temperature | -5~2℃ |

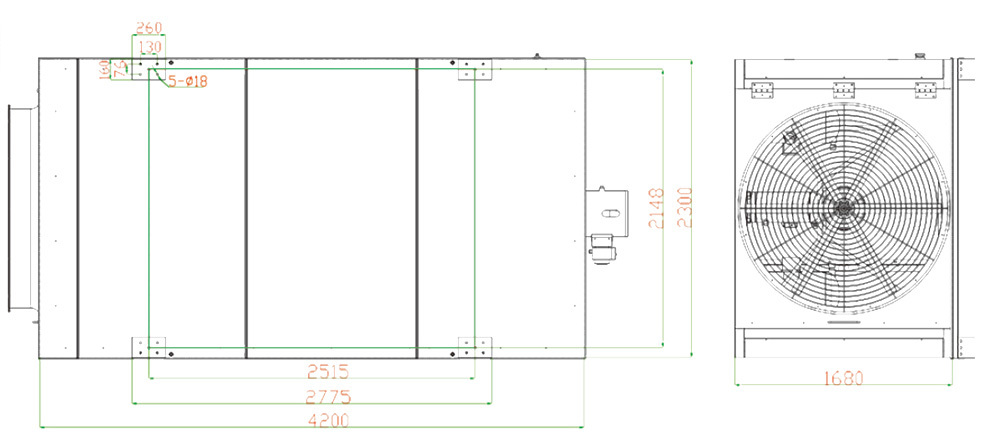

| Out dimension | 4200*2300*1680mm |

| Weight | 3600kg |

Note:1.The technical parameters on product nameplate shall prevail. Custom design can be made according to specific user needs. Reserve the rights to change the parameters wit-hout prior notice due to continual improvements.

2.Regrigerant can be customized designed to use R134A, R407A or R410A.

Dimension figure:

SF-075DG-DL Dimension figure

Patent grants:

|

A type of aircraft ground air conditioning unit (patent No,:ZL201520899859.0); |

Aircraft ground air conditioning unit (patent No,:ZL201630132533.5); |

|

A type of installtion of aircraft ground air conditioning unit (patent No,:ZL201620330337.3); |

A type of air filter for aircraft ground air conditioning unit (patent No,:ZL201620331111.5); |

|

A type of rain test device for aircraft ground air conditioning unit (patent No,:ZL201620331111.5); |

A type of soft connection structure for aircraft ground air conditioning unit (patent No,:ZL201620331194.8); |

|

A type of air valve assembly (patent No,:ZL201620334261.1); |

A type of heating air duct assembly (patent No,:ZL201620330746.3); |

|

A type of evaporator air distribution device (patent No,:ZL201620331051.7); |

A type of evaporator assembly (patent No,:ZL201620334254.1); |

Applicable models:

B727-100/200,B737;A318,A319,A320,A321and so on.